- March 21, 2023

- Posted by: Mike Kramer

Client

CSI collaborated with Phase One, a general contractor, to design, construct, and commission two customized robotic cells for an automobile parts manufacturer in Ontario.

The Challenge

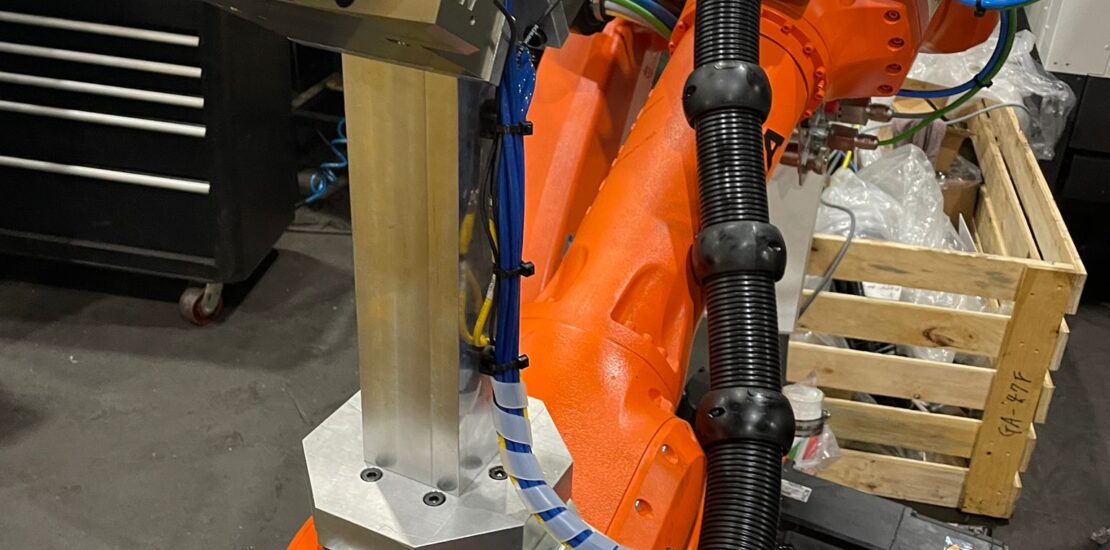

This project involved designing and building robotic cells for a client who needed to transport parts through a grinding process. The client required a six-axis robotic arm with both pneumatic and electric power to move parts from an in-line gravity conveyor system to a style check station, and then to a precision grinder. Parts would then have to be cleaned, put through in-line quality assurance, and placed back onto the conveyor system.

One of the main challenges we faced was ensuring that the robotic arm could maneuver well within the confined space of the work cell while also defining the area within as a safe zone to protect employees in the manufacturing facility. Our team needed to position and design the robot arms to move quickly enough to process parts within the required cycle time while also moving slowly enough to transport parts safely and without damage.

Another challenge was ensuring that the identification of each part was accurate and that the grinder could adjust accordingly. We had to ensure that the identification system worked seamlessly with the Kuka robotic arm, Siemens (Simatic S7 – CPU 1510) PLC Controller, and the Okuma grinder.

The client also required a quality assurance system to ensure that each part met its standards before being returned to the conveyor. We had to implement a laser-based quality assurance system to quickly and accurately assess each part.

Overall, this project required our team to design and build a complex system that integrated multiple technologies, including robotics, pneumatics, and laser sensors to achieve the client’s desired cycle time and production goals.

Supply Issues

During the development of these robotic cells, we faced significant challenges due to supply issues caused by the COVID-19 pandemic. The standard equipment used in North America for these types of builds was not readily available.

To address this challenge, we had to source alternative machines and instrumentation from around the world, including HMI displays (Siemens), robotic arm bases (Kuka), and grinding machines (Okuma).

Purchasing this unfamiliar equipment meant that our team needed extra time to understand how to use the equipment safely and correctly. Additionally, most instructions and standards for this equipment were intended for integration of the equipment in Asian and European markets, which required our team to spend more time ensuring they fully understood how to use these tools safely and effectively before integrating them in North America.

Another issue that arose from using international parts was communication and safety standards. North America, Europe, and Japan have different electrical standards for voltage, and their proprietary Ethernet protocols do not intuitively communicate with each other. This required additional effort to ensure that the various technologies used in the robotic cells could communicate effectively and safely.

The Solution

CSI implemented a complete controls design and then iteratively commissioned the project’s electrical system, communications, touch screen control,s and pneumatic systems. Our team developed custom-designed HMI screens, PLC (Siemens) programs, ethernet communications, and safety guarding switches to ensure all the equipment worked together intuitively and safely.

In response to the supply issues caused by the pandemic, we sourced alternative suppliers of high-quality equipment from around the world. The team purchased robotic arms from Kuka, HMI displays (Siemens), and PLCs (Siemens) from Germany and the client obtained the grinder (Okuma) from Japan. Our team of engineers took the necessary time to fully understand how these machines worked and how to use them safely. We worked with equipment manufacturers where possible and focused on translating texts when needed. Additionally, we used our prior knowledge to figure out these machines within the project’s timeframe.

We also adapted to the different electrical and Ethernet communication standards used in Europe, Japan, and North America. Our team used Ethernet IP gateways to bridge the various communication protocol networks, allowing the different types of equipment to communicate with each other. We also used appropriate power supplies as required to provide the electrical power to the European equipment while also allowing our control voltage to be 24VDC as required to ensure safe electrical standards throughout the build.

As we created our electrical prints and plans, we transposed the symbols of the international equipment to meet North American standards. For more information on assessing equipment for safe use in North America, please refer to our downloadable PDF.

The Outcome

Both robotic cells were completed for our client, and they were very happy with the results. Thanks to the robotic implementation, they will see a return on investment in less than 12 months and improved cycle times.

Most importantly, through implementing this automation, our manufacturing client can continue to competitively yet profitably meet the demands of their customers and the marketplace.

Our client also has access to a team who is specifically educated in the design and build of these custom robotic cells and knows that if preventative maintenance or modifications are necessary, they can turn to our team for a quick resolution.

If you’re looking to introduce robotic cells to your facility and need assistance in design, build, and commissioning, contact CSI today. We’ll gladly discuss your needs and help you create a plan.

For over 20 years, CSI has provided expert engineering services as a Control Systems Integrator in both Canada and the United States. Our automation and electrical system designs reach throughout industries and across the world. With experienced and knowledgeable engineers and skilled workers, we are a key component in our customers’ automated control solutions.

- Designing & Building Robotic Cell Controls for an Automobile Part Manufacturing Facility - March 21, 2023

- Why AI in Manufacturing is the New Norm - February 15, 2023

- Creating Safety Retrofits for Inverted Power & Free Conveyor Access - January 17, 2023