PLC Programming Services for Automated Machinery and Process Control

Our team at Control Systems International (CSI) are PLC programming services experts, with experience in PLC technology, utilizing PLCs as part of electrical control systems design for automated machinery, and process control. We use the most current PLC technology, including safety PLCs, as a component for our electrical control system designs. We create unique and proprietary operating systems specific to your needs, ensuring the program created is custom to you. Brands such as Siemens, Schneider, Rockwell, Telemacanique, and Pilz are all supported and utilized by our team.

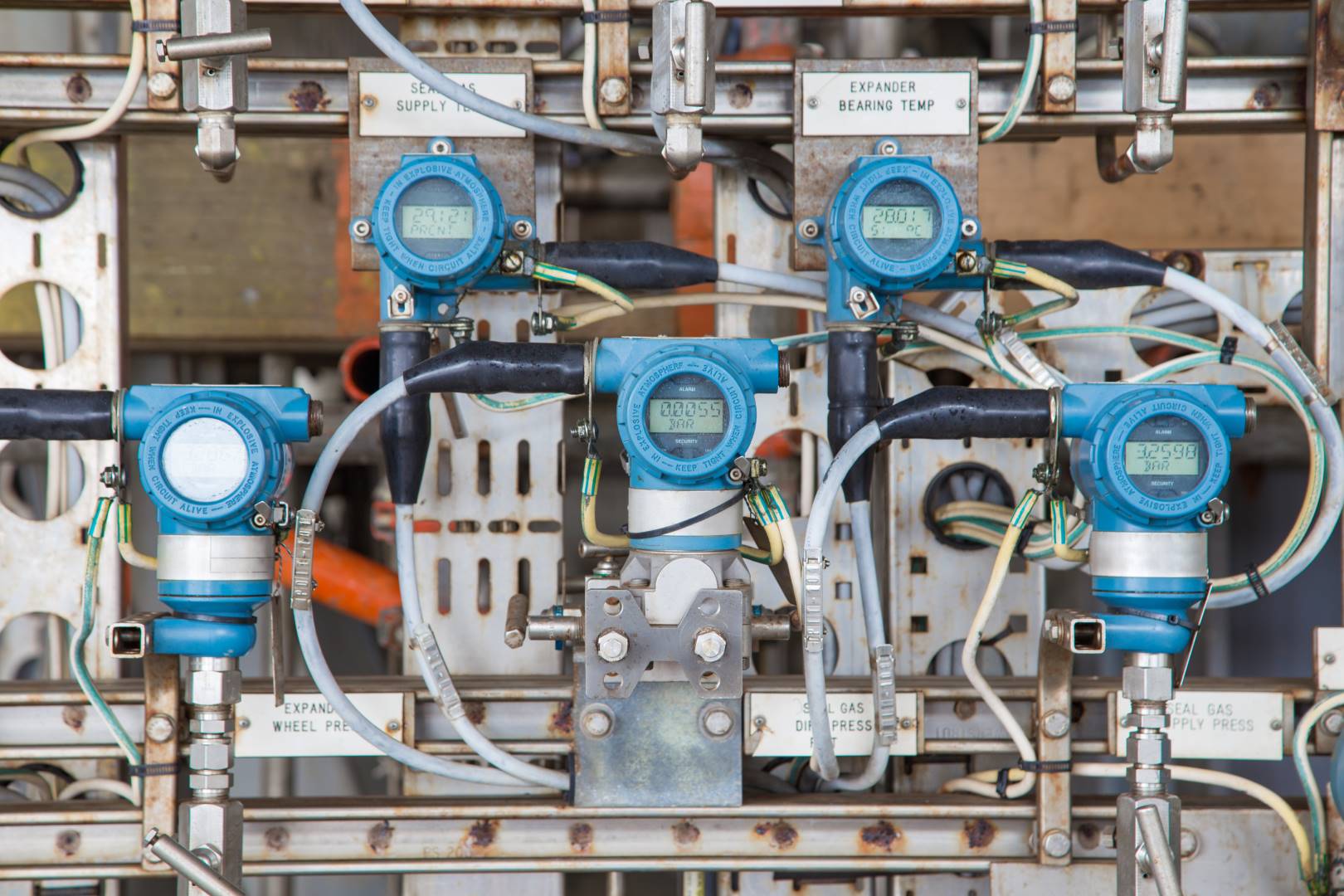

Collecting Complex Analog Instrument Data

Data Archiving for Product Traceability

Notification Systems

Derivations of Complex Decision-Making Algorithms

Integration to Graphical Interfaces for Machine Control

Complex Recipe Management

Assess your equipment for safe use in the workplace with our downloadable guide.

Request a Service Consultation

Contact us to request a consultation where we will examine your current productions and make recommendations on how to optimize your facility. Whether you’re looking for a turnkey solution or a custom-designed controls system, we manage and facilitate projects of any size.